Mr. Taylor's background was in steam quarry cranes of the fixed pole type made in Scotland circa 1839, perhaps the first ever of the type. He then build winch-based cranes on quays from about 1842. It is believed he moved to Birkenhead about 1850. In December 1853 he filed an important patent - No. 3004 for - "Certain improvements in raising and lowering weights".

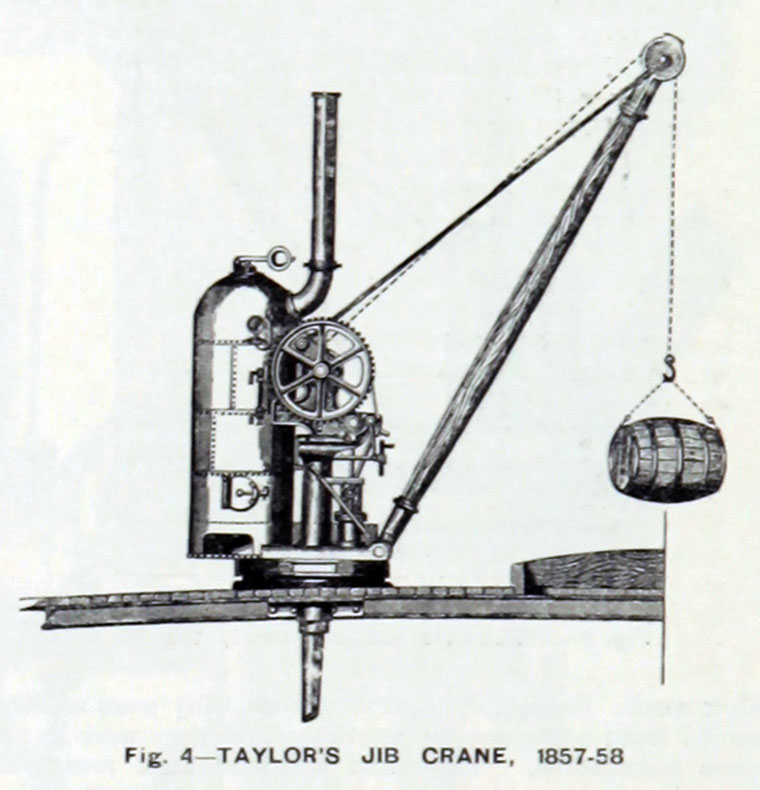

This covered the first use of reversing-link steam-gear in cranes, and relegation of heavy flywheels - which last are dangerous in any crane with low-speed engines. By eliminating stop/start dog-clutch reversal, and being extremely compact, this was ideal for ships winches, and perfect for cranes. Then in 1859, Mr. Taylor made the machine below - the first, "properly-commercial" 4-motion steam rail-mounted crane in the World. As perfect in conception and execution in 1859 as almost-identical machines still being made 100 years later !

James Taylor next built a series of larger travelling cranes. These, along with those of Appleby Brothers of London, showed the World how it should be done. His 1867 4-powered-motion machine below has all essential characteristics (other than live race) of a travelling and slewing machine : (1) a forward-mounted hoist drum (2) a top mounted worm-controlled luffing drum (3) a substantial, extended superstructure (4) a rear over-hanging boiler to counterweight load (5) a bogie carriage (essential for many later cranes)(6) No flywheel other than disc cranks.

James Taylor was also very important in respect of large cranes. In 1875, he build the world's-largest sheerlegs for Portsmouth - 140 feet tall; test load 120 tons - and was early leader in large steam-crab gantry cranes. In 1876 he build the first large iron-structured rectangular-type Blocksetting crane for Ceylon (putting aside a smaller iron-made machine made by Stothert & Pitt for Karachi in 1867)

From 1869 to about 1885 he made the large fixed slewing cranes which provided the only heavy-lifting power at main ports from Britain to Australia, Japan and Peru. Among features first used by him in large steam cranes were the full-circle, three-part, live slewing race, and the rolled, tapered and riveted jib - the exact means of constructing same at the time remains a mystery today. About 1887 Taylor's substantial and important firm at Birkenhead literally disappeared overnight. Unfortunately for the Industrial Historian, remnant archives amount to almost zero.

Source Above : © Bruce Ward, Historian, Historical Crane Society 2012